The new I frame concept offers improved torsional properties in comparison to the fixed frames. It has the same elasticity as the chassis. Driving thus becomes a pleasure and service life of vehicles is extended.

Maintenance-free components, the comprehensive bolted concept as well as the consistent, use of standard components, make the operating and maintenance costs pleasantly unassuming and easy to calculate.

The truck is protected from damage by the transmission of forces to the support legs. The forces from the boom are transmitted directly to the four support legs. The truck chassis isn’t used for force transmission and is, therefore, not loaded with torsion. It ensures not only quieter pumping operation but also a long service life of the whole truck.

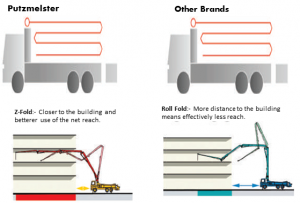

With its Z-fold boom, the M 36-4 combines an optimum reach on a 3-axle chassis with added features and versatility, all at a gross weight of under 25t. The great flexibility of the Z-fold system and the narrow cross-section of the arm assembly significantly improve the M 36-4’s manoeuvrability. It enables jobs to be completed as fast and as simply as possible. Overcoming obstacles on construction sites is no big deal, because the M 36-4 is even able to reach places that would usually require larger machines or boom extensions.

It is also possible for the boom to slip into structures of up to 10m in height if the machine is very close to the building. This creates a noticeably longer net reach. Thanks to its Z-Fold system, the M 36-4 is ready to place concrete in no time, as not all of the arms need to be unfolded before pumping begins.

The cross support developed by Putzmeister which is stable and reliable, saves time and space without compromising on safety.

Construction sites generally have restricted set-up conditions because they are located in urban areas or along busy roads. Therefore, with the optional OSS (One Sided Support), the telescopic support legs can be securely placed in minimal spaces between obstacles and hence reduce the width by 1/3 from the original 7m. An important advantage of the OSS is that full use is made of the net reach for the fully supported side.